Free Micro Mixer

Line-up

| Format | FMM-mini | FMM-1 | FMM-4 |

|---|---|---|---|

| Processing capacity | Up to 27L/hr | Up to 120L/hr | Up to 480L/hr |

| Working pressure | 0.5 to 5MPa | 0.5 to 5MPa | 0.5 to 5MPa |

| Continuous use temperature | Max.80ºC | Max.80℃ | Max.80℃ |

| Main unit weight | 0.6kg | 1kg | 2.7kg |

| Installation space | W0.8m×D0.5m (main unit 45×45×50mm) | W0.8m×D0.5m (main unit 45×45×50mm) | W1.2m×D0.6m (main unit 80×80×70mm) |

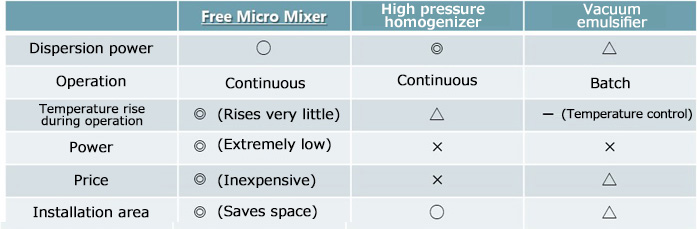

Comparison with other emulsifying devices

Free Micro Mixer features

| Features | 1. Enables continuous operation without clogs |

|---|---|

| Applications | Food/Ceramics/Chemical products/Pharmaceuticals |

| Industries | Electronics industry/Feed industry/Food industry/Chemical industry/Pharmaceutical industry/Ceramics industry and fine ceramics |

| Specifications | Other |

| Remarks | |

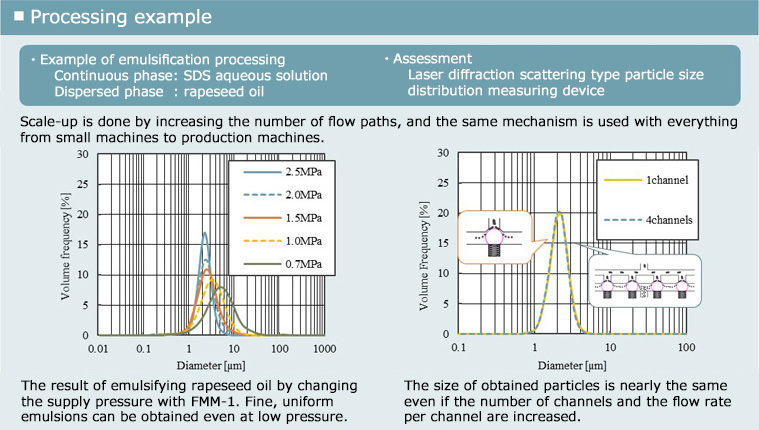

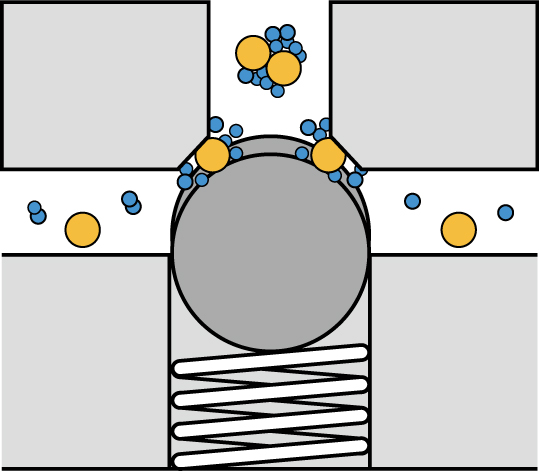

| Principles and structures | Uses balls to create very narrow gaps of several μm, and emulsifies and disperses using the complex flow fields (elongation flows, shear flows, contraction flows) created when liquids pass through these gaps. |