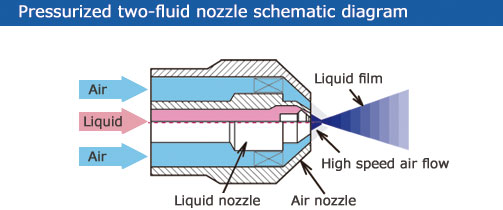

Pressurized two-fluid nozzle

| Format | APN-100 | APN-400 | APN-600 | APN-800 | APN-1000 |

|---|---|---|---|---|---|

| Spray volume (kg/h) | 0 to 100 | 0 to 400 | 0 to 600 | 0 to 800 | 0 to 1,000 |

| Spray water pressure (MPa) | 1.0 | 1.4 | 1.5 | 1.4 | 1.6 |

| Features | 1. Adjusting the air flow volume makes it possible to control droplet particle size. |

|---|---|

| Applications | Food/Ceramics/Chemical products/Organic solvents/Environmental countermeasures/Other |

| Industries | Feed industry/Food industry/Chemical industry/Vehicle industry/Ceramics industry and fine ceramics/Luxury goods/Environment related |

| Specifications | Atomizing method (nozzle) |

| Remarks | ― |

| Principles of atomiz | Performs effective atomization by forming a liquid film into a donut shape and then concentrating a high-speed airflow on the film. Therefore, by combining a medium-pressure water pump (1 to 2 MPa) and a Roots blower (40 kPa), motive power demonstrates atomization performance of average particle size of 40 to 60 μm. |