Twin Jet Nozzle

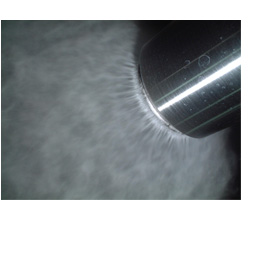

Conventionally, the only way to produce fine particles 10 μm or smaller was to either suppress throughput or lower solid content concentration. The twin jet nozzle we developed enables the mass production of fine particles without applying such restrictions.

■ Click here for a detailed video relating to the twin jet nozzle↓

| Models | RJ-10 | RJ-25 | RJ-50 | TJ-100 | TJ custom* | TJ |

|---|---|---|---|---|---|---|

| Spray volume (L/hr) | < 10 | 10 to 25 | 25 to 50 | 50 to 100 | 100 to 1000 | > 1000 |

| Features | 1. Reduces atomization air volume by using collisions to atomize. |

|---|---|

| Applications | Ceramics/Chemical products/Pharmaceuticals/Organic solvents/Other |

| Industries | Electronics industry/Chemical industry/Pharmaceutical industry/Environment related |

| Specifications | Atomizing method (nozzle) |

| Remarks | ― |

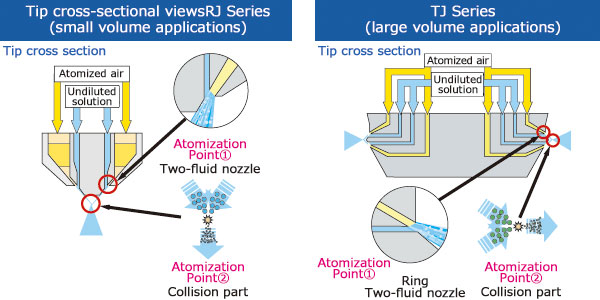

| Mechanism | 1. As a first step, liquid is sheared with air to produce gas-liquid jet flows. |