Spray Cooler

Examples of actual operational results

| Stock solution | Coagulation temperature (ºC) | Throughput (kg/h) | Operating conditions (ºC) | Average particle size (μ) |

|---|

| Fatty acid | 60 | 2,800 | 15 to 50 | 200 |

|---|

| High molecular polymer | 120 | 1,000 | 10 to 50 | 300 |

|---|

| Low molecular polymer | 160 | 1,500 | 5 to 50 | 700 |

|---|

| Plastics | 155 | 3,200 | 40 to 50 | 2,000 |

|---|

List of Functions

| Features |

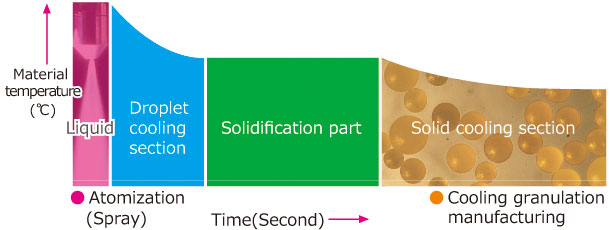

1. Obtains beautiful spherical particle products.

2. Obtained products have superior fluidity, superior mechanical strength, and thus suffer little damage during handling.

3. Operation is simple, automatic operation is possible, and maintenance is easy.

4. Device is rigid and has a small footprint.

5. Optimal for continuous granulation in mass volumes.

6. Combining devices enables continuous un-manned operation. |

| Applications |

Chemical products/Pharmaceuticals |

| Industries |

Chemical industry/Pharmaceutical industry/Petroleum resins |

| Specifications |

Atomizing method (rotary disc)

Atomizing method (nozzle)

Product recovery method (main unit, cyclone dual-point collection)

Product recovery method (cyclone single-point collection)

Product recovery method (bag filter single-point collection)

|

| Remarks |

― |

*1: Made-to-order according to model type and your required specifications

*2: Heat source standard specifications vary based on model type